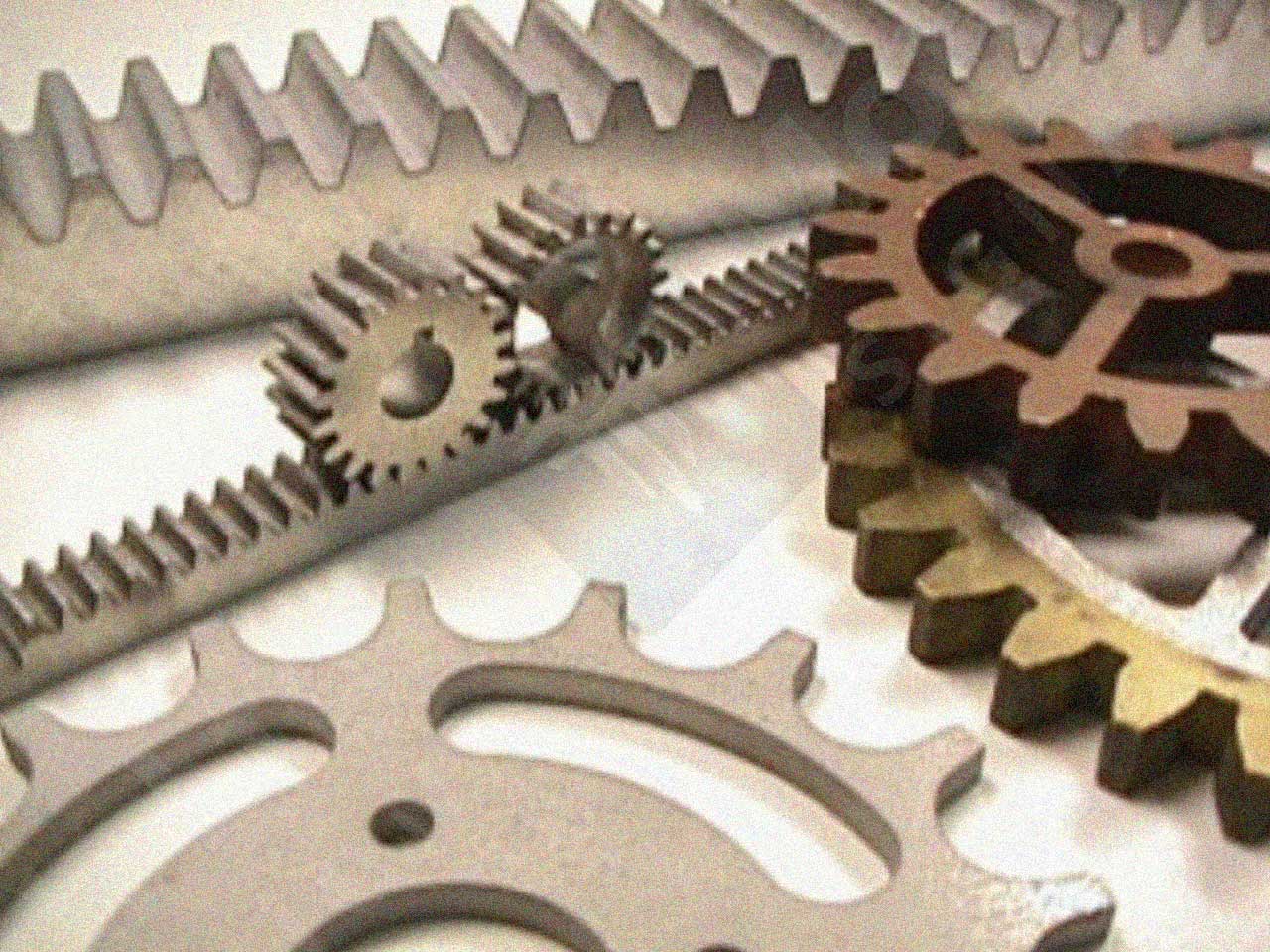

- Application Areas in Short Manufacturing

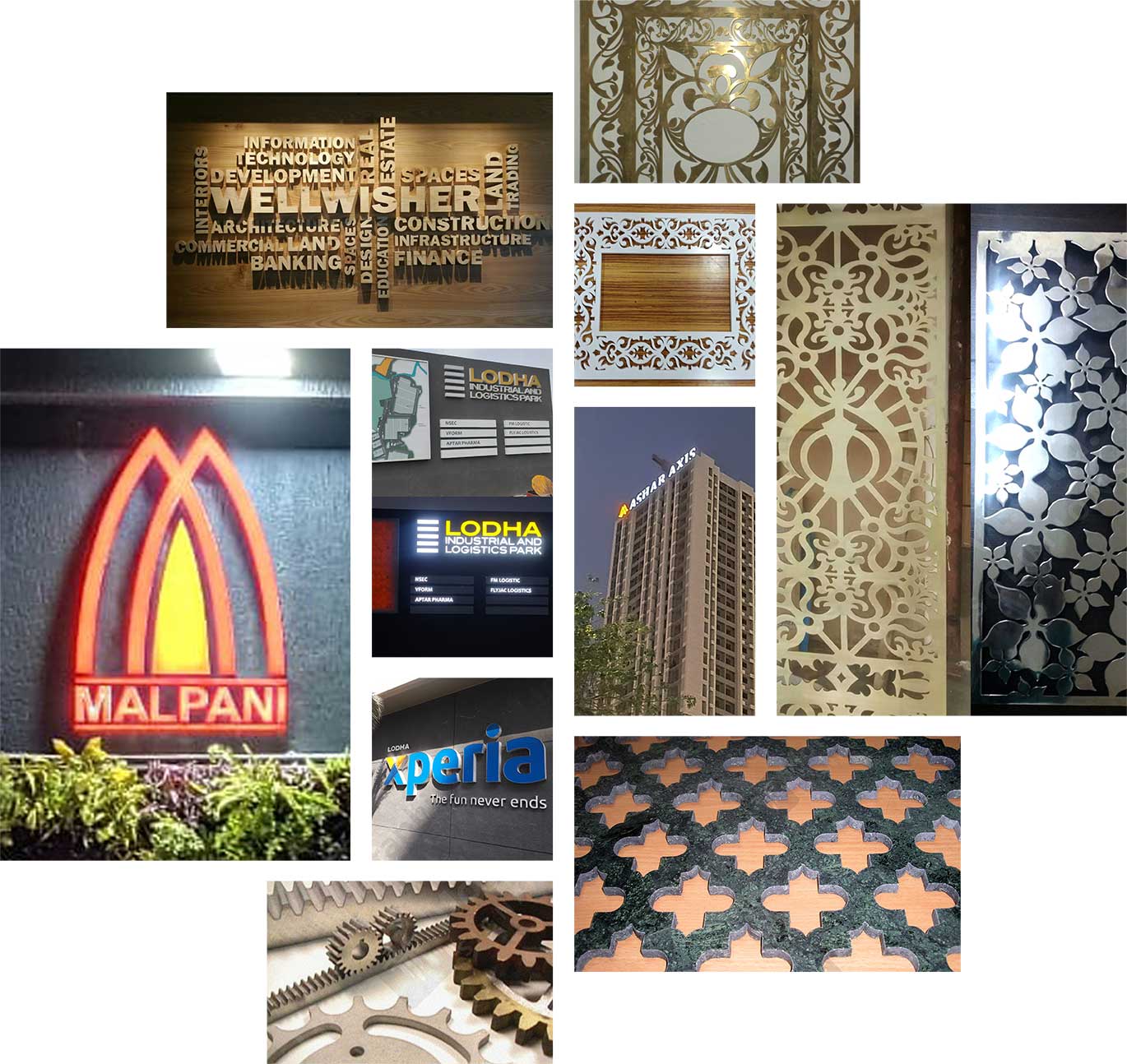

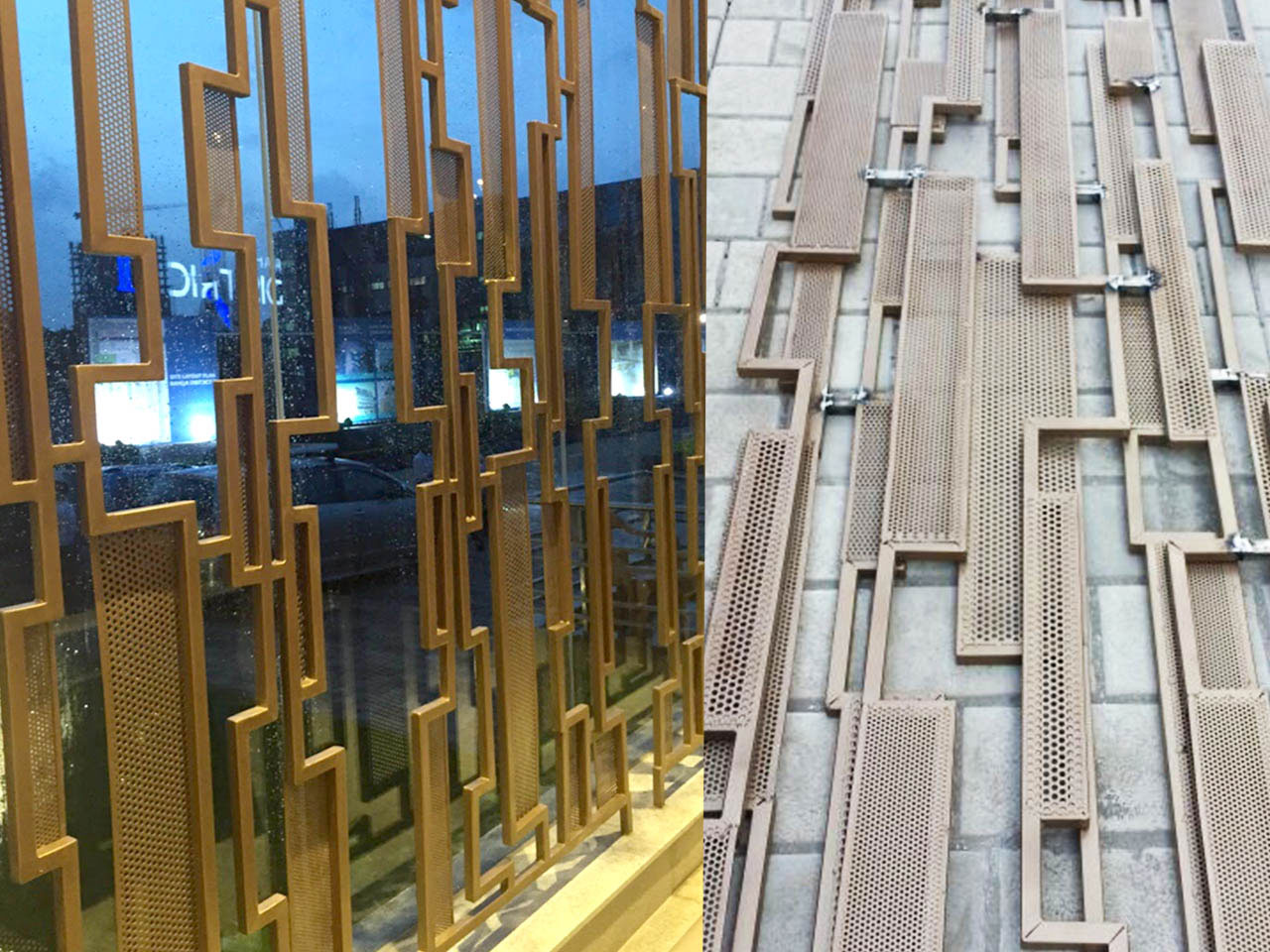

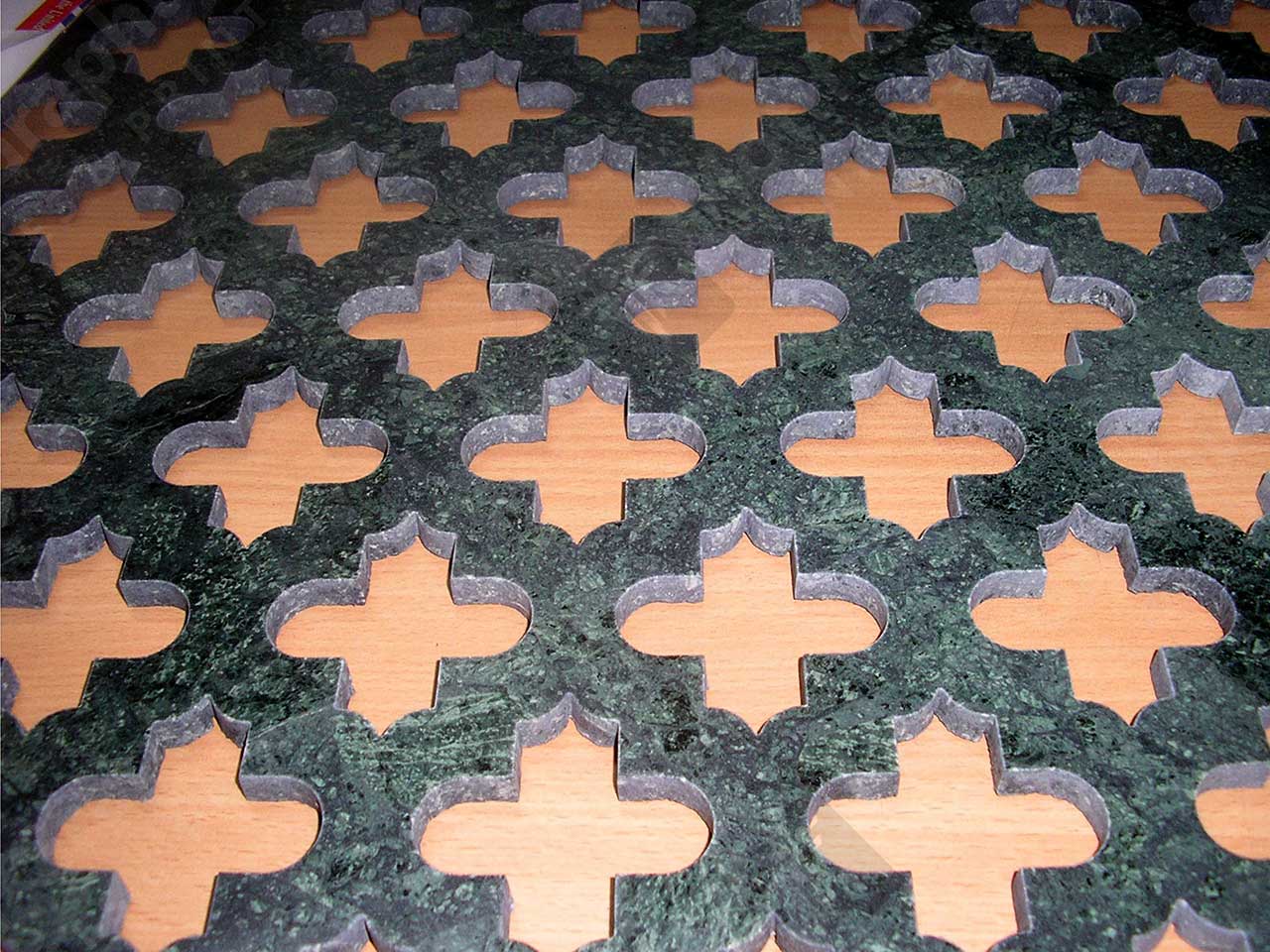

- Architecture & Construction

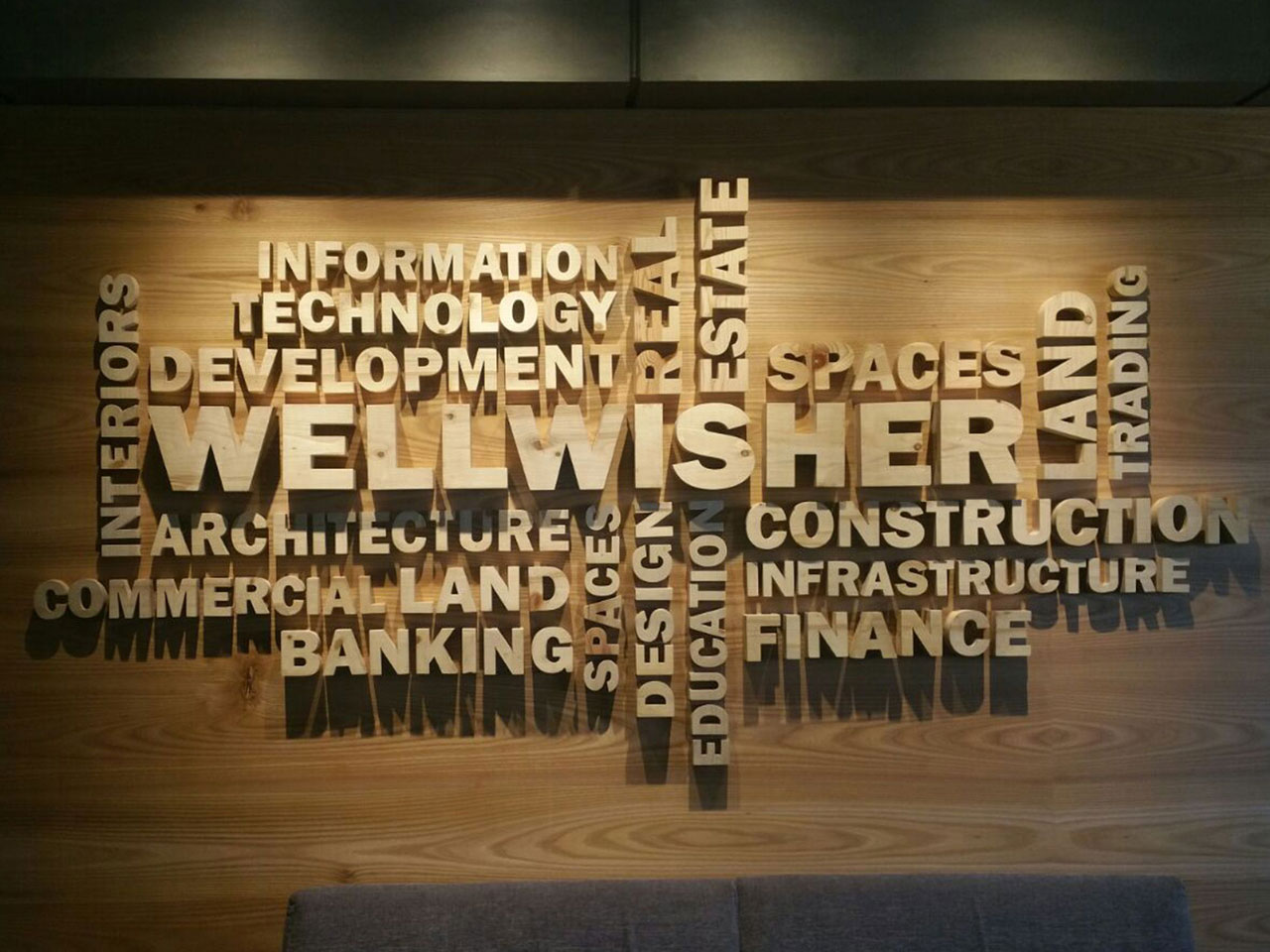

- Signage & Art

- Glass Industry

- Medical Devices

- Tooling

About Us

Lorem, ipsum dolor sit amet consectetur adipisicing elit. Tempore ipsam alias quae cupiditate quas, neque eum magni impedit asperiores.

Contact Us

- 121 King St, Melbourne VIC 3000, Australia.

- hello@barky.com info@barky.com

- (312) 895-9800 (312) 895-9888